Rapid self-discharge testing solution

I. Industry Background

On January 11th, the China Association of Automobile Manufacturers released the production and sales data of automobiles in 2023.

The data shows that in 2023, the production and sales of automobiles in China reached 30.161 million and 30.094 million respectively,

increasing by 11.6% and 12% year-on-year, setting a new record high and achieving double-digit growth. China has remained the world's

largest automobile producer and seller for the 15th consecutive year. Among them, the penetration rate of new energy vehicles has

reached 31.6%, with an annual sales volume of 9.495 million, increasing by 37.9% year-on-year.

With the increase in the number of new energy vehicles, the requirements for their safety and stability are also getting higher and higher.

As the core component of new energy vehicles, the safety and stability of batteries are particularly prominent.

Self-discharge of lithium batteries is an important parameter for evaluating battery performance. How to accurately detect the

self-discharge parameter is particularly important. The causes and impacts of self-discharge in lithium-ion batteries.

Self-discharge reactions in lithium-ion batteries are inevitable. Their existence not only leads to a reduction in the battery's own capacity

but also seriously affects the battery matching and cycle life of lithium-ion batteries. The self-discharge rate of lithium-ion batteries is

generally 2% to 5% per month, which can fully meet the usage requirements of individual batteries.

The self-discharge rate refers to the percentage of the battery's capacity that is lost automatically over a period of time when the battery

is not in use. Generally, the self-discharge rate of lithium-ion batteries at room temperature is 5% to 8%.

The self-discharge rate is also known as the charge retention capacity, which refers to the battery's ability to retain the stored charge

under certain conditions when the battery is in an open circuit state. It is mainly affected by factors such as the manufacturing process,

materials, and storage conditions of lithium-ion batteries.

II. Industry Pain Points

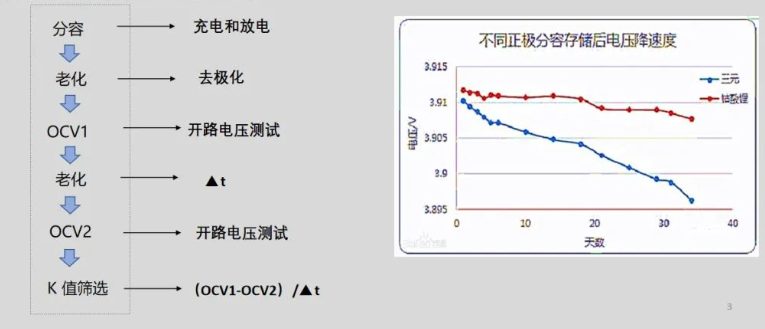

Currently, the self-discharge of lithium batteries is mostly determined by K value testing. K value testing calculates the voltage drop of

the battery within a unit of time, and the product's K value is obtained through calculation. Here, the unit of time is measured in days,

usually 5 to 7 days. This results in a long confirmation time for a battery's self-discharge, thereby affecting the delivery cycle.

How to quickly and accurately test the self-discharge problem of products has become the main pain point in the industry for

self-discharge testing.

III. Solutions

Based on a thorough understanding and research of user needs, Ruijie Intelligent has developed the RJ6962 rapid self-discharge

testing system. The product applies a highly stable voltage signal to both ends of the battery, compensates for the open-circuit

voltage inside the battery with the voltage signal, and calculates the self-discharge value inside the battery.

This significantly reduces the self-discharge testing time. When combined with a constant temperature box,

this product can be applied in various scenarios such as product verification laboratories, product development laboratories,

and material development verification laboratories for rapid self-discharge testing, reducing the testing time to within 30 minutes.

This greatly shortens the waiting time for customers' product development and verification.