Solution for Battery Open Circuit Voltage and AC Internal Resistance Sorting

I. Industry Background

With the rapid development of battery energy storage, new energy vehicles and other industries, the market's requirements for battery

performance indicators are getting higher and higher. Battery packs, as a collection of multiple batteries connected in series or parallel,

effectively enhance energy storage and output capabilities and are thus widely used. However, battery consistency, a key issue affecting

battery pack lifespan and cost, directly restricts its development and application.

Ideally, during the charging and discharging process of a battery pack, the voltages of all batteries should rise or fall simultaneously,

and the capacities, voltages,self-discharge rates, and internal resistances of different batteries should remain consistent. This ensures

that all batteries are fully charged or discharged at the same time, without overcharging or overdischarging any individual battery,

achieving the effect of 1+1=2.

However, in the actual production of battery packs, there are often significant or minor differences among different batteries.

This can lead to situations where,to prevent the poorest-performing battery in a battery pack from being overcharged or overdischarged,

other batteries are not fully charged or discharged, resulting in wasted performance of those batteries.

Therefore, consistency issues typically cause the cycle life of a battery pack to be

only 1/3 to 1/5 of the designed lifespan of a single battery. More severe consistency issues can even cause thermal runaway in the battery

pack, leading to equipment damage or personal injury.

II. Application Requirements

Based on the basic parameter indicators of batteries, the following six manifestations of battery consistency can be summarized.

1. Capacity consistency: The rated capacity refers to the minimum amount of electricity that a battery can discharge under certain conditions.

During the battery

production process, the sorting process of capacity classification is carried out to ensure that the rated capacity of the same battery pack is

within a certain range.

2. Internal resistance consistency: Battery internal resistance is generally divided into DC internal resistance and AC internal resistance,

corresponding to the DCIR and ACIR tests in the battery production process. Under normal circumstances,

batteries with low internal resistance have strong discharge

capacity, while those with high internal resistance have weak discharge capacity. Moreover,

high internal resistance generates a large amount

of Joule heat, causing the internal temperature of the battery to rise, resulting in a decrease in the battery's discharge working voltage

and a shortened discharge time, which has a significant impact on battery performance and lifespan. In the same battery pack,

the internal resistance of lithium batteries should be controlled within a certain range.

3. Constant current ratio consistency: The constant current ratio refers to the ratio of the constant current charge capacity of a single battery

to the total charge capacity

under constant current and constant voltage. The higher the constant current ratio, the better the battery performance. During the battery

production process,the sorting process of capacity classification is carried out to ensure that the single batteries in the same lithium battery

pack are in the same constant current ratio category.

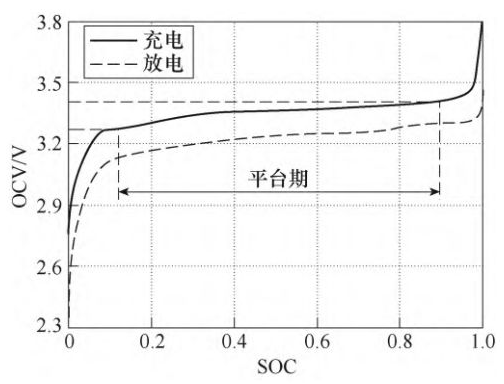

4. Discharge platform consistency: From the OCV-SOC curve of the battery, it can be seen that there is a platform during the battery discharge

process where the OCV changes little while the capacity is constantly decreasing. During this period, the battery is in a stable discharge state.

During the capacity classification process, batteries can be charged and discharged under certain conditions to obtain

the OCV voltage corresponding to the discharge platform of

different batteries. In the same lithium battery pack, the single batteries should be in the same discharge platform category.

5. Consistent Open Circuit Voltage: Open circuit voltage refers to the potential difference between the two electrodes of a battery when it is

not being charged ordischarged. Through the OCV testing process, the open circuit voltage of the battery can be tested to ensure that the

voltage of individual cells in the same battery pack is controlled within a certain voltage difference range.

6. Consistent Battery Batch: Batch consistency means that the electrical performance of the same model of lithium batteries produced

using the same batch of materials, the same process, the same equipment, and at the same time is basically consistent.

The same batch of batteries should be selected for the same battery pack.

If the quantity of one batch is insufficient, batteries from adjacent batches with the same process should be selected.

III. Solution

The precision battery internal resistance tester developed by Ruijie Intelligent is fully compatible with the OCV testing process of lithium

battery cells and can quickl and reliably test the AC internal resistance and open circuit voltage of the cells. At the same time,

the tester is equipped with a sorting function.Press the number 6 on the test interface to open it. The sorting range and other

parameters can be set in the sorting settings. The sorting results can be output to the production line PLC through IO or

transmitted to the production line industrial computer or other upper computers through the serial

port to ensure the consistency of the internal resistance and open circuit voltage of individual cells.